Creation of a robotic arm

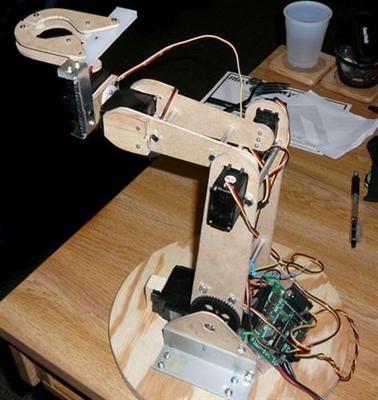

The main shoulder joint is driven by a Hitec HS-805BB servo, a real monster. I like this servo a lot because it can pretty much give whatever you ask from it. Stall torque is rated at 343oz-in and I also had a gear reduction on the shoulder joint that increased the torque by about 1.75x.

The elbow joint was a lot of fun because I chose to use two HS-311 servos in conjunction. This configuration provides stability for both sides of the joint and bumps up the maximum torque. Since I still had a lot of mass to control outset from the elbow the extra capacity was necessary. These servos produce around 42oz-in of stall torque, which was sufficient for this design. In the actual controller code the servos rotate in opposite directions, so I had to be concious of them trying to fight each other. Overall this joint performed the best and was super fast!

Here's a side view of the whole 'bot. The gripper mechanism is pretty neat but not functional. You can sort of deduce this from the one piece of aluminum sheet metal holding it on. I ran out of time to make it work well, but decided to attach it for asthetic purposes. The basic mechanism has a rotating cam that spreads the two fingers. The grip is supplied by spring returns on each finger. It also features a passive locking system on the cam when the fingers are completely closed.

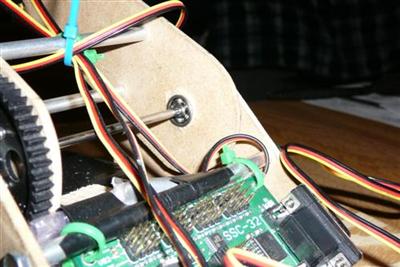

The large gear on the shoulder joint gave me a lot of problems since it wasn't a very high quality part. The interface between the HS-805BB servo and the shoulder gear was difficult to maintain and the joint frequently slipped when it was moved too fast. In an attempt to maintain that joint better I added the large aluminum brackets you see here. They did help a lot, but still couldn't maintain the level of consistency I wanted from the arm. I plan on re-machining everything from aluminum when I build the snare-bot arm (similar design) for strength and precision.

You can see the press-fit bearings used at the shoulder joint. It was pretty epic putting precision bearings into fibrous hardboard material. They fit quite snug, looked pretty, but were totally over-engineered for this choice of construction material. You can also see the controller board here -- a Lynxmotion SSC32. This board is my favorite serial servo controller I've used so far with 32 outputs, daisy chaining capabilities, a wide range of baud rates, and a relatively compact footprint.

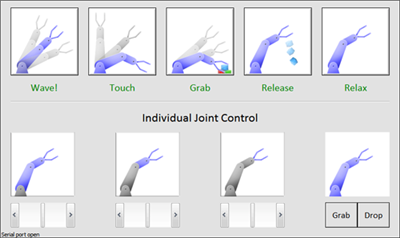

The controller board was connected by serial cable to a laptop running Windows and a serial servo controller program I wrote. This is the "kid" version of the software which has pre-scripted macros for cool demonstrations. I typically use a stripped down version of this program to run all of my 'bots that use the SSC-32. If you are interested in the board go to Lynxmotion and check it out. If you get or have the board and want the basic software (8 channel control and terminal window) send me an email!

Labels: lynxmotion, robot arm, robotics, servos

Subscribe to DanShope.com

Subscribe to DanShope.com